High activity despite the downturn

15 July, 2015 8:50 Del Del DelAlthough tougher times now prevail in the oil and gas industry, SINTEF Molab is once again experiencing great demand from its customers in the industry. The expertise of SINTEF Molab is very important in order for the offshore industry to feel confident that the materials they use possess the characteristics they should, so that accidents and incidents are avoided.

“90 per cent of what we do in our department is targeted towards the oil and gas industry. Last year was a year of crises for our part, and we had to lay off and release a number of employees. Things were bleak, but from early this year there has been considerable activity for our part. This despite the fact that you can constantly read in the media that these are bad times for the oil industry,” says Roger Lund, Department of Materials Testing at SINTEF Molab AS.

“It’s not easy to look ahead, and we can only guess how the autumn will be,” he adds.

SINTEF Molab’s department for materials testing has 14 employees with backgrounds including machinists, technicians, metallurgists, engineers and civil engineers. And the majority of these have many years of experience. Kjell Arne Hansen is one of the old hands at the company. He will tell you that the work here demands a great deal of knowledge and expertise in many fields.

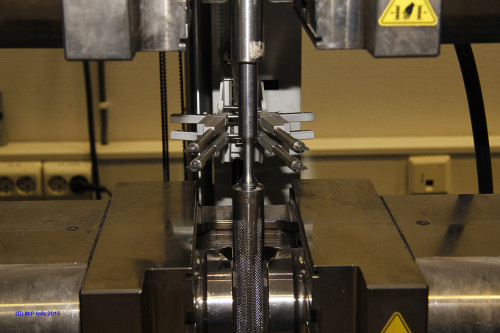

“We conduct material testing of different metallic materials such as steel, aluminium and copper alloys. The testing of offshore welding procedures has been a significant focus area since the engineering industry started deliveries to the Norwegian continental shelf.

SINTEF Molab principally performs destructive testing and metallography and offers metallurgical consultancy services,” says Kjell Arne Hansen. He continues:

“We also carry out damage analysis when unwanted fractures in materials occur. A key tool in connection with this work is the use of SEM, which stands for Scanning Electron Microscope. There are very few electron microscopes in Norway, and we have two in daily operation. Using SEM we can identify components down to element level,” he adds.

SINTEF Molab tests according to all known national and international standards. The majority of the work concerns the testing of welding procedures.

“We verify the strength and material properties of the steel and the welds. We test all materials, including plastic and concrete,” says Hansen.

Supplies to the world market

Kjell Arne Hansen has worked with materials testing for 34 years and has been involved in the changes that the business has experienced.

The laboratory has a history dating back to the old A/S Norsk Jernverk, and was the ironworks’ laboratory that tested the quality of their production. SINTEF Molab was established as an independent company in 1989 after the restructuring of Norsk Jernverk AS. The business is a subsidiary of SINTEF where Mo Industripark AS is a minority owner.

“We have had to follow the changes experienced by the market and gradually improve in other areas. We have become adept at quickly changing direction. Previously testing for Ruukki Profiler AS accounted for as much as 50 per cent of our work. When they stopped operating we targeted the offshore market. Now this, as I said, is our main industry,” says Hansen.

Today, SINTEF Molab is one of the biggest industrial, independent laboratory businesses in Norway.

“We deliver what we test to technology owners who are global leaders, who in turn deliver to the world market. There is hardly an offshore oil field in the world that we do not test materials for,” says Roger Lund and continues:

“In our department we work on fairly short term, usually from one to two weeks, and take on urgent work. You have to stay cool under pressure. We have many customers and enter their projects at an early stage. Frequently they do start their projects until we have tested the materials and submitted reports,” says Lund.

“We are an extremely important partner for our customers. We are their guarantee and assurance that the materials they use satisfy demands and that everything is analysed correctly.

For example, we have tested pipelines laid on the seabed for many decades, and verify that the material will maintain its specifications with regard to corrosion resistance and strength, to ensure this is safe. If something is wrong, we will find it, and frequently inspectors from the major oil companies are present to witness testing in connection with their projects. They must testify that the work we conduct is pursuant to the standard required,” concludes Kjell Arne Hansen at SINTEF Molab.

Tags: Grottoes Steel AS, Mo Industrial Park, Mo Industripark, Molab AS, Sintef, SINTEF Molab AS

Categorised in: Gulesider, On the front page

Del Del Del