Certification opens new markets for Industrial AM

27 January, 2026 11:03 Del DelIndustrial AM in Mo Industripark is now certified by DNV for metal 3D printing. This marks an important step for the company and for an industry looking toward more efficient and sustainable production methods.

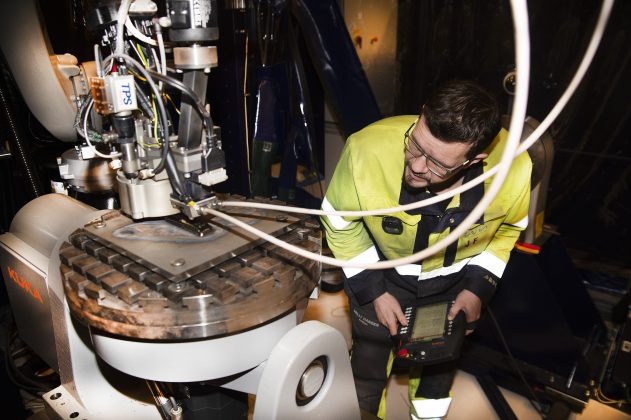

“We have received a certificate confirming that both the company and the printer meet the standards required for 3D printing by DNV,” says Rolf Skogvold, Project Manager at Momek Robotics, co-owner of Industrial AM and Business Developer at Industrial AM.

With the ST-B203 certification, the company can now supply parts to customers with strict requirements for quality and traceability, including those in the oil and gas sector.

“That is absolutely essential. When delivering components for critical systems, you must be able to document that the quality is at least as high as with traditional manufacturing methods. This certification gives us that assurance,” Skogvold explains.

The model Joakim Fagerbakk is working on here will soon become a finished metal product manufactured in Industrial AM’s large-format printer.

On the path to full material certification

The facility and processes at Industrial AM are now certified. The next step is material certification.

“We are working with four different materials and expect to have the certifications completed by January. That will open up entirely new opportunities. So far, we have mainly supplied non-critical components, but with fully approved materials we can supply to significantly more applications,” says Skogvold.

Industrial AM is collaborating with major industry players such as Equinor and Aker BP, who have supported the initiative both financially and technically from the beginning.

“They are also exploring how they can adopt this technology in their own value chains,” says Skogvold.

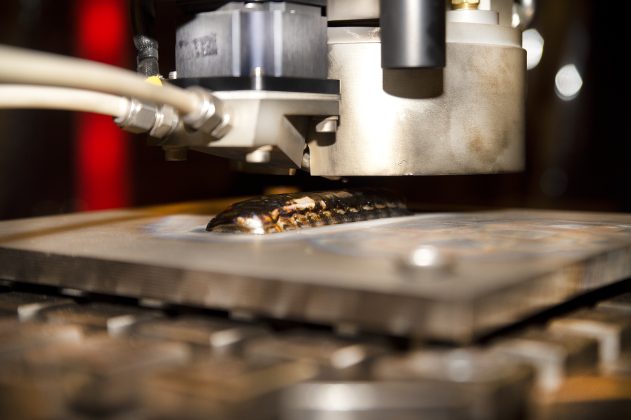

In the software, the 3D model is sliced and translated into a precise print program. This is how the metal components are built layer by layer.

Local, efficient and sustainable

Traditionally, metal components are cast or machined from solid blocks – a process that is both time-consuming and resource-intensive.

“If you want to make a component today, you typically start with a large block of stainless steel and machine away perhaps 80 percent of the material. With 3D printing, we build the object layer by layer using welding wire and remove only 3 to 5 millimeters of excess material afterward. That saves both time and resources,” says André Moen Eide, Managing Director of Momek Robotics.

Along with increased flexibility and quality, Skogvold highlights several benefits of producing components locally in Mo Industripark.

“We are located in the middle of an industrial cluster where companies order parts from all over the world. That means long transport routes, tolls, high costs and the risk of delays. By producing locally, we can ensure shorter delivery times and reduce both waste and emissions from transport. And we can deliver in just a few days. It offers an entirely new level of agility,” he says.

Categorised in: Frontpage, Industripark News

Del Del